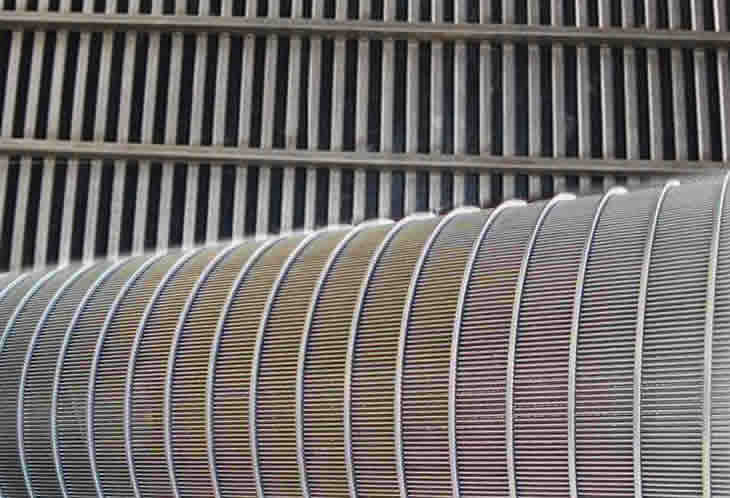

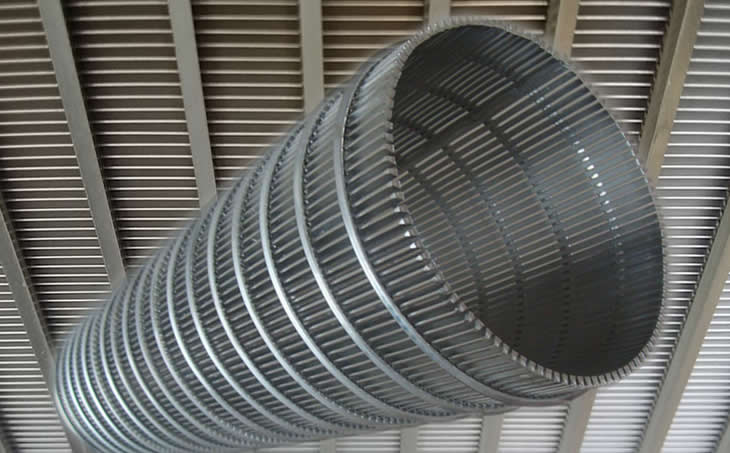

Wedge wire screen is manufactured with supporting rods and wire screening strips. The supporting rod can be round wire, triangular wire or trapezoid wire. The screening wire is triangular wire (V-shaped wire). A precise slots is achieved and profile wire screen is formed by modern welding technology. Wedge wire, also called profile wire, has a rigid screen construction with the capability of withstanding heavy loads. The slotted wire screen is characterized by accurate opening, low possibility of blanking, perfectly smooth surface and high open surface ratio. Different wires may be used, various slots in one wedge wire screen, as well as different distances between supporting wires or bars can be created. Flat panels, cylinders and curved bends are common forms applied for wedge wire filter products.

Slots range from 0.05mm to maximum size 3500mm x 4000mm.

Structures:

The profile wire is made with rectangular support bars (rods) which enable the panel to span longer distances without intermediate support bars. Welding each surface wire at every junction with support rods creates a rigid structure that transmits vibratory forces more effectively with less energy loss. Continuous opening and high porosity of the wedge wire can greatly increase the water flow area when used as water well screen. Trapezoidal filter cylinder offers a solid structure, high porosity, and accurate poring. The scontinuous slot wire wound structure makes wedge wire ideal screen material for water well and oil well drilling.

Features of Wedge Wire Well Drilling Sand Control Screen:

Wedgewire well screens has sturdy constriction and good mechanical property. The V-shape section plane can avoid blockage and make sure of the unimpeded water. The consecutive slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the Water Well Screens under the great pressure, so it can filter sand better. The V-type profile of the structure can avoid clogging and ensure smooth flow of water and continuous long-term effective use of the pores. Also, Trapezoidal wire cylinder filter is easy for washing, long service life, safe, reliable, comprehensive and low cost.

Materials and Choosing:

Popular well screen materials are stainless steel 304, 304L and 316.

Materials – ferrite: AISI 430 (1.4016); austenite: AISI 304 (1.4301), AISI 304L (1.4307), AISI 202 (1.473), AISI 316 (1.4401), AISI 316L (1.4404), AISI 317LN (1.4439), AISI 904L (1.4539), AISI 321 (1.4541), AISI 316Ti (1.4571), Duplex: 329 LN (1.4462), 439 (1.4410);Special: 2.4360, 2.4610, 2.4816

Slot:Standard from 0,05 mm. Smaller on available on customer's request.

Support wire / bars:According to the slotted wedge wire screen catalogue - Typ I: 10x3, 10x2, 12x3, 15x3, 18x2, 20x2, 30x2 and special type Q: Q35, Q55

Working wire: Standard wire - Typ Sb: Sb6, Sb8, Sb12, Sb18, Sb 22, Sb28, Sb34, Sb42, Sb60, Sb70, SbA50 and the special wires type Sbb: Sbb34, Sbb38, Sbb42, Sbb48, Sbb50, Sbb76, 2,4x5, 3x6,5.

Dimensions:max. 3500x4000 mm; standard work – other sizes available on customer's request.

Choosing: Different wire diamaters, slots, forms different filter rating.

Application:

Stainless steel water well screen can be used with the deep well pump for the deep well operation, also used in the water-treating equipments and the environmental protection. Mainly:

1.The sea water transforming into the industrial water and life use water via desalination treatment, running water treatment, water softening treatment.

2. The petroleum industry: The petroleum product terminal filters and filter screen for the chemical acid, the alkali liquid, the ethyl alcohol and other organic solution recycling filters.

Specification:

| SIZE (inch) | O.D (mm) | SLOT (inch) | LENGTH (m) | Collapse Strength (psi) | Tensile Weight (ton) | Wire size (mm) | RODS (mm) |

| 4 | 117 | 0.040 | 3 | 395 | 6 | 2.2*3.0 | 3.8mm/22 |

| 4 | 114.3 | 0.040 | 3 | 395 | 6 | 2.3*3.0 | 3.8mm/22 |

| 6 | 168.3 | 0.040 | 3 | 252 | 8 | 2.3*3.5 | 3.8mm/32 |

| 8 | 219.1 | 0.010 | 3 | 399 | 10.5 | 3.0*5.0 | 3.8mm/48 |

| 8 | 219.1 | 0.020 | 3 | 370 | 10.5 | 3.0*5.0 | 3.8mm/48 |

| 8 | 219.1 | 0.040 | 3 | 323 | 10.5 | 3.0*5.0 | 3.8mm/48 |

| 10 | 273.1 | 0.010 | 3 | 206 | 11 | 3.0*5.0 | 3.8mm/50 |

| 10 | 273.1 | 0.020 | 3 | 191 | 11 | 3.0*5.0 | 3.8mm/50 |

| 10 | 273.1 | 0.040 | 3 | 167 | 11 | 3.0*5.0 | 3.8mm/50 |