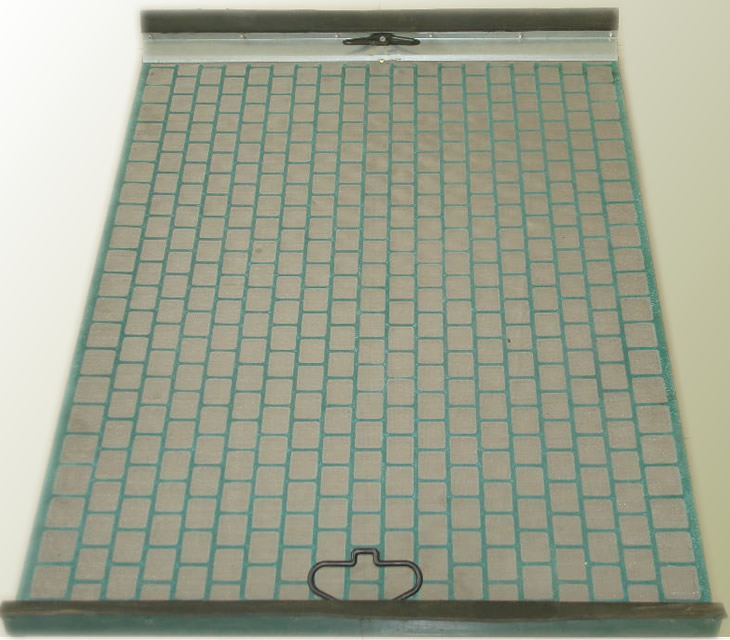

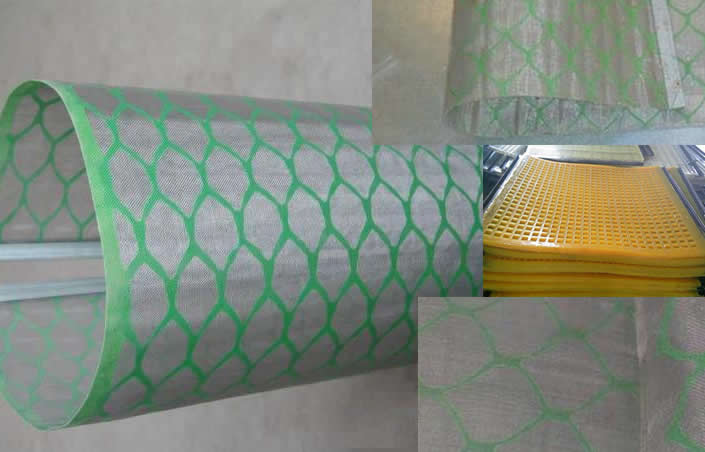

We supply hook strip flat screen and soft screen used for FLC503 and 2000 shale shakers, also other brands and modes. This type of shale shaker screen for oil field application is designed with Hook Strip fully bonded and pretensioned. Popular models for export: Single layer mesh screen (20 x 30 mesh) in oblong opening; Single layer mesh screen ( 20 x 4o mesh) in oblong or rectangular holes for rig components; Single layer mesh screen ( 20 x 60 mesh) in oblong opening. The bonding tubular strip design help maintain cut point integrity by stabilizing the sandwich screen and increasing durability. The flat screen can become soft screen when the primary structure is one block composed of 2 to 4 layers bonded together with no rigid backing plate. Oil Field Application Shale Shaker Screen constructed with Hook Strip fully bonded and pretensioned size: 60 inch x 48 inch.

The flat screen with hook strip utilize an advanced frame design and unique mesh combinations to effectively and efficiently separate detrimental drilled solids from drilling fluid.

The products are usually consists of two or three layers stainless steel wire cloth glued on the hole in the metal plate. The stripped metal screen has special rubber plug to repair net surface damage, this design can effectively save time, reduce the production cost. The screen is replacement mesh which can be repaired and re-screened using the stainless steel plugs, upplied with the panel or by application of, silicone rubber.

A pin-and-hole screen securing system also available.

Material:

Wire Mesh Materials: Stainless Steel SUS304, 316, 316L, etc.

Width:585mm~1230mm

Length:1053mm~1250mm

Thickness:10mm~30mm or as your request

Mesh:16~325 mesh

Screen layer:2 or 3 Layers

Perforated plate material:Carbon steel.

Features:

1. Made of high strength proforated steel sheet and high quality micron precise screen mesh;

2. Improved work efficiency;

3. Easy for installation and disassemble;

4. Extended service life of screen mesh and hooks;

5. Improved energy transfer from the shaker basket to the screen, thus faster solids separation;

6. Replacement of screen or mesh available leading to cost savings and downtime minimization;

7. Heat resistant, abrasion resistant and corrosion resistant.

Application:

Hook stripped shale shaker screen with crimped mesh or fine wire cloth is used as flat panels for mud drilling in oilfield and other vibration solid control dewatering.

Specifictions:

| Screen Model | Range of Mesh Cloth | Weight (Kg) |

| SS-(Soft) | 20-250 | 1.5 |

| SS-5250 ( Soft ) | 20-250 | 2.0 |

| SS-ZCN | 80-210 | 2.4 |

| SS-NS | 80-210 | 2.8 |

| SS2-8 | 20-80 | 2.1 |

| SS2-8 | 20-80 | 4.5 |