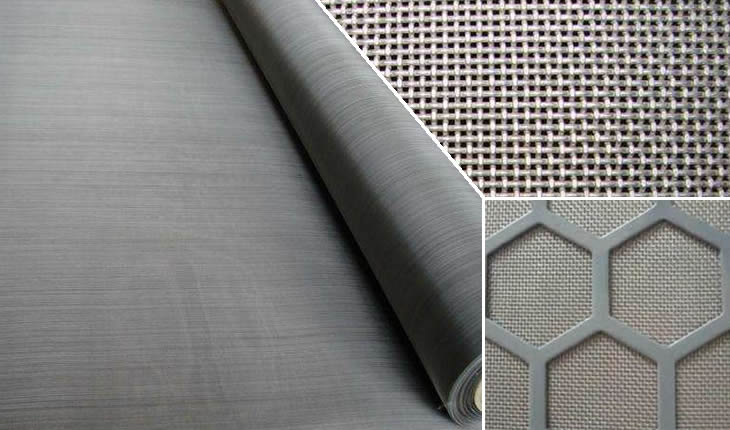

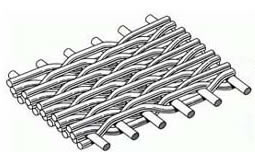

We supply two types of Stainless Steel Meshes according to wire forms applied: crimped wire or round wire. This page mainly introduces Woven Mesh of Stainless Steel Round Wire used for making of shale shaker screen and various filter sieves. Stainless steel wire mesh enjoys excellent resistance against acid, alkali, heat and corrosion. It is extensively used as filter and screening media in processing of oil, chemical, food processing, wire mesh filter, sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and other industries.

Wire Materials: SUS/AISI 201, 202, 302, 304, 310, 310S, 316, 316L, etc.

AISI 304: This type is the basic stainless alloy mostly commonly used for wire cloth/mesh weaving. It offers excellent property against rusting and oxidation.

AISI 304 L: Materials similar to 304, with reduced carbon content for better weaving.

AISI 316: Stainless stabilized by the addition of 2% molydbenum. It has better resistance to pitting corrosion than the other chromium-nickel stainless steels and high strength at elevated temperatures. Other mechanical properties and fabricating characteristics are similar to AISI304.

Wire cloth woven of T-316 has extensive use in chemical processing when better corrosion resistance is required than the regular chromium-nickel types.

AISI 316 L: Very similar to AISI316, yet with the reduced carbon content for better wire cloth weaving.

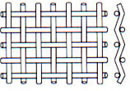

Square Opening Stainless Steel Mesh of Plain Weave

Plain weave is the most simple weaving type with each weft wire passing over one and under one warp wire, and each warp wire passing over one and under one weft wire. The weft wire has the same diameter with the warp wire. Among all woven wire products, Plain woven wire mesh has the maximum opening and the minimum thickness of the fabric.

Plain weave is the most simple weaving type with each weft wire passing over one and under one warp wire, and each warp wire passing over one and under one weft wire. The weft wire has the same diameter with the warp wire. Among all woven wire products, Plain woven wire mesh has the maximum opening and the minimum thickness of the fabric.

Features: Square aperture, high flow through, relative high open area as result of less pressure drop during filtration.

Uses: Stainless steel plain woven wire mesh is suitable for all kinds of filtration up to 63 µm.

Standard mesh counts per inch for stainless steel wire mesh with square opening: 2mesh / 3mesh / 4mesh / 7mesh / 10mesh / 12mesh / 16mesh / 18mesh / 20mesh / 24mesh / 30mesh / 35mesh / 40mesh / 50mesh / 60mesh / 70mesh / 80mesh / 90mesh / 100mesh / 120mesh / 150mesh / 180mesh / 200mesh / 250mesh / 300mesh / 325mesh / 350mesh / 400mesh / 450mesh / 500mesh

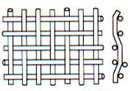

Twill Weave Square Hole Mesh:

Twill Weave Square Hole Mesh:

Twill weave is applied for weaving of heavy meshes and thicker wire fabric with square opening compared with plain weave. Each weft wire passes over two and under two warp wires, and each warp wire passes over and under two weft wires. The wire diameter for both (warp and weft) is mostly the same. Twill Weave allows a thicker wire and is suitable for heavy meshes. The wire position of Twill weave wire mesh is less stable compared with plain weave.

Features: Twill woven wire mesh has square aperture, it is less rigid than plain weave, easy deforming. It is a strong wire cloth due to ratio of wire diameter and aperture, mostly used for filtration between 25 to 130 μm.

Specifications:

| Mesh Count Warp x Weft |

Wire Dia mm |

Wire Dia inch |

Aperture mm |

Aperture inch |

Micron Rating |

| 100 x 100 | 0.1250 | 0.0049 | 0.1295 | 0.0051 | 130 |

| 120 x 120 | 0.0939 | 0.0037 | 0.1168 | 0.0046 | 117 |

| 165 x 165 | 0.0482 | 0.0019 | 0.1041 | 0.0041 | 104 |

| 200 x 200 | 0.0584 | 0.0023 | 0.0685 | 0.0027 | 68 |

| 250 x 250 | 0.0533 | 0.0021 | 0.0482 | 0.0019 | 48 |

| 300 x 300 | 0.0355 | 0.0014 | 0.0482 | 0.0019 | 48 |

| 300 x 300 | 0.0400 | 0.0016 | 0.0431 | 0.0017 | 45 |

| 325 x 325 | 0.0355 | 0.0014 | 0.0406 | 0.0016 | 41 |

| 350 x 350 | 0.0304 | 0.0012 | 0.0431 | 0.0017 | 43 |

| 400 x 400 | 0.0304 | 0.0012 | 0.0330 | 0.0013 | 33 |

| 500 x 500 | 0.0254 | 0.0010 | 0.0253 | 0.0010 | 25 |

Dutch Plain Woven SS Mesh

Dutch Plain Woven SS Mesh

Weave: Dutch plain woven wire mesh/cloth/fabric has straight warp wires and close weft wires. The weft wires lie as close as possible against each other in a linen weave forming a dense strong material with small, irregular and twisting passageways that appear triangular when diagonally viewing the weave.

Features: Dutch plain woven wire cloth is more solid than square or rectangular mesh, offering relatively high open area, suitable for all kinds of pressure filtration.

Uses: Dutch plain woven wire mesh is mainly used in the following fields:

1, Industrial filter cloth and apparatus of separation;

2, in gas and liquid filtration and other medium separation;

3, Precision pressure filters, the fuel filter, vacuum filter, as filter materials, aerospace, oil refining, pharmaceutical, sugaring, oil, chemical, chemical fiber, rubber, tire manufacturing, metallurgy, food, health research,etc.

Specifications:

| Mesh Count Warp x Weft |

Wire Dia mm Warp x Weft |

Wire Dia inch Warp x Weft |

Micron Rating |

| 8 x 85 | 0.360 x 0.320 | 0.0140 x 0.0125 | 320-340 |

| 12 x 64 | 0.580 x 0.420 | 0.0230 x 0.0165 | 265-285 |

| 14 x 88 | 0.500 x 0.350 | 0.0200 x 0.0140 | 215-235 |

| 24 x 100 | 0.350 x 0.250 | 0.0140 x 0.0100 | 115-125 |

| 30 x 150 | 0.230 x 0.180 | 0.0090 x 0.0071 | 95-100 |

| 40 x 200 | 0.180 x 0.140 | 0.0070 x 0.0055 | 70-75 |

| 50 x 250 | 0.140 x 0.114 | 0.0055 x 0.0045 | 55-60 |

| 80 x 400 | 0.125 x 0.071 | 0.0050 x 0.0028 | 40-45 |

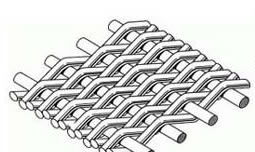

Dutch Twill Woven Wire Mesh

Dutch Twill Woven Wire Mesh

Weaving Method: This type of woven wire mesh/cloth/fabric is a kind of twilled woven wire product combined with the Hollander Weave or Dutch weave. This pattern enables a strong wire cloth with super fine filtration. Compared with common Twill Weave, the Dutch twill allows a thick structure and a fine filter material. The weft wires and the warp wires intercross two above and two below, inverting the intersections of the warp wire at an established distance, obtaining a rigid, stable and robust type of wire mesh fabric.

Uses: Dutch Twill also known as Crossed twilled wire mesh are basic components in the production of filter used in chemical industry, medicine, petroleum, telecom-communication, scientific research units and so on.

Specification:

Stainless Steel Wire Cloth (Dutch Twill Weave) |

||||

| Mesh | Wire Diameter (d) | Aperture | ||

| Vertical | Horizontal | Vertical | Horizontal | Microns |

| 20 | 250 | 0.25 | 0.23 | 110-120 |

| 32 | 360 | 0.23 | 0.15 | 100-110 |

| 40 | 400 | 0.18 | 0.14 | 90-110 |

| 50 | 500 | 0.14 | 0.11 | 70-90 |

| 50 | 600 | 0.14 | 0.09 | 60-70 |

| 80 | 800 | 0.12 | 0.07 | 45-65 |

| 165 | 800 | 0.07 | 0.05 | 24-26 |

| 120 | 1000 | 0.08 | 0.055 | 27-28 |

| 165 | 1450 | 0.07 | 0.04 | 16-18 |

| 325 | 2300 | 0.038 | 0.025 | 8-9 |

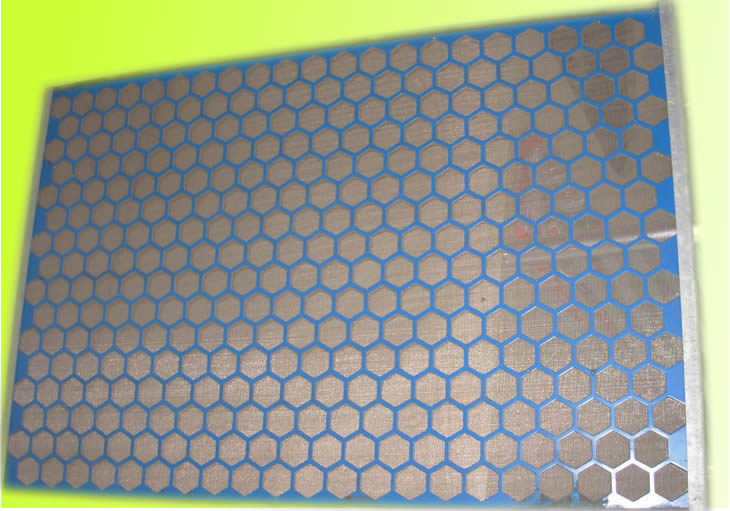

Application Illustrations:

We offer stainless steel mesh with accurate and consistent micron size apertures and smooth surface to ensure the best work effect for sieves screening and circular screening machines. SS mesh is used in making of hook strip screens, framed shale shaker screen, pleated mesh filter elements and various sieves and filters.

Learn more about the finished screening products processed from Stainless Steel Woven Wire Mesh.