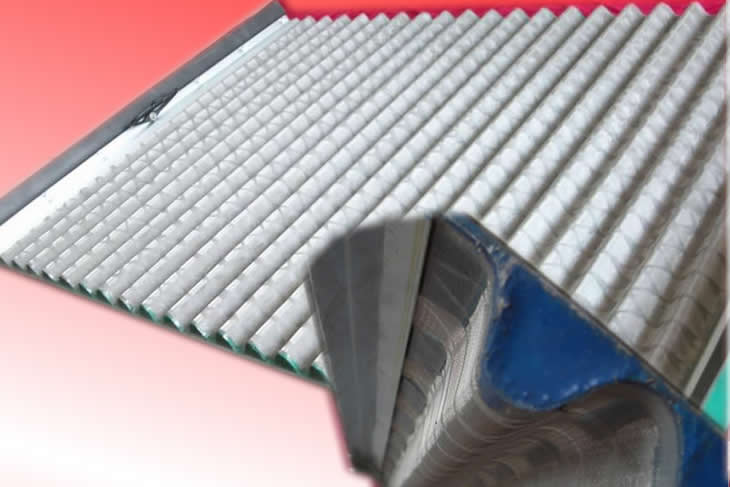

Pleated shale shaker screen panels offers increased screening area with waved filter cloth bonded to metal backing plate. Compared with Flat Mesh Screen, the pleated wave-shape metal screen enjoys more filtration surface to 125% to 150% percent that of a flat screen. Waved Vibrating Screen can load more drilling fluid flow. The filter cloth can be common woven wire mesh or crimped woven mesh.

Metal Screen Structures:

Waved screen has typical mesh cloth that appears regular waves. It is made with two or three layers of stainless steel mesh cloth of round or crimped wire, laminated into wave shape panels. The effective area of this dimensional screen panels with waves can be greatly increased and in this way, the work efficient is greatly enhanced.

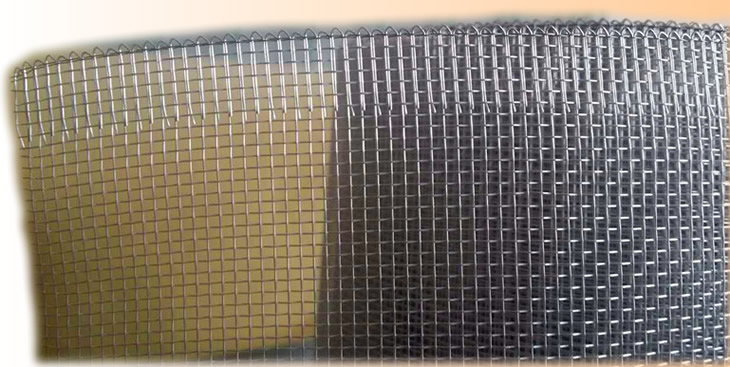

Mesh Cloth Materials:

Carbon steel wire (galvanized or not)(45#, 70#, 72A, 82B)

Manganese steel wire (65Mn, 30Mn)

Stainless steel wire (201,202, 304, 316, 304L, 316L)

Mesh wire diameter: 0.5-16mm

width: under 2m about

Weaving style:

Plain weave, twill weave, dutch weave

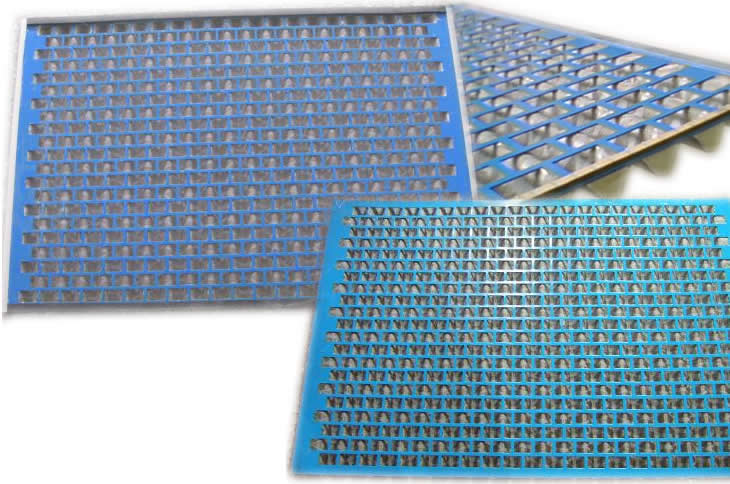

Features:

The screen fits all standard Vibrating shakers, allowing the most efficient use of existing equipment;

It will enable large cost savings and improvements in shaker performance;

Multi-layer pleat vibrating screens are designed to maximize solids removal capabilities while significantly reducing costs associated with drilling fluid and disposal.

Application:

This multi layer plate screen can be used in oil, coal and mine, and various filtering. It is popularly used to reduce the percentage of drilled solids in the mud system, hence to reduce the drilling cost in oil and gas industry.

Specifications:

Mesh Cloth Sizes:

| Items | Mesh Range | Dimension (Length x Width) | Weight(KGS) |

| SS -1 | 20-325 | 585×1165mm | 12 |

| SS-2 | 20-325 | 635×1253mm | 13.5 |

| SS -3 | 20-325 | 913×650mm | 12.5 |

| SS -4 | 20-325 | 720×1220mm | 17 |

| SS -5 | 20-325 | 712×1180mm | 17 |