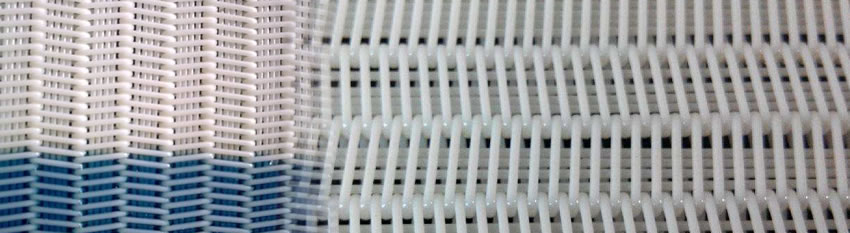

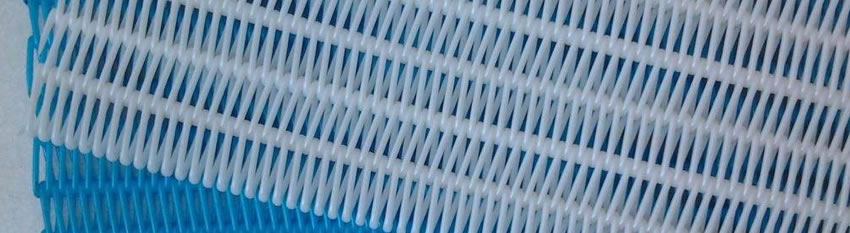

We supply polyester mesh screen widely used in shaker screening, paper making, filter belt press, coal washing and sludge treatment dehydration uses. Weaving types include plain weave and spiral mesh. Polyester plain woven Processed from first class monofilament meeting Finland srandard, the polyester spiral dryer fabric has the characteristics of stable property and long work time.

Materials: Polyester Monofilament yarn or wire.

Applications:

Paper making industry, food processing, salt industry, pharmacy and medicine processing, environment protection, process hides, shoe-making, clothing, coal mining, ceramics etc.

Polyester mesh enjoys the following features as dewatering belts:

- High strength

- Stable under high tension

- High resistance against abrasion

- Seamless - the seam has exactly the same strength of the belt

- Can be repaired easily on site

- Durability, smoothness and good dirt release

- Filled or unfilled to achieve different filtration characteristics (Air permeability: 250 to over 1000 CFM)

- Sealed edges for lasting, economical solutions

- Widths up to 9 linear

- Standard lengths to 60-80 m or make to order

- pH range 2 to 8

Spiral Mesh Specifications

| Weaving Type | Model | Thread Diameter | Air permeability | |

| (mm) | (m3/m2h) | |||

| Warp | Weft | |||

| Large Loop | 4070 | 0.9 | 1.1 | 20000±500 |

| Medium Loop | 3868 | 0.7 | 0.9 | 18500±500 |

| Small Loop | 3252 | 0.52 | 0.7 | 15000±500 |

Also Supply Micron Polyester Monofilament Filter Fabric for Grading and Bolting:

We offer a wide range of filter products for manufacturing powders, chemicals, and pharmaceuticals, gas filter for air conditioning and air purification, and liquid filters. The filter cloth offers good air and water permeability easily prevent filter cloth blinding, rapid peeling off, good regeneration.

Features:

-Precision mesh, well-distributed aperture, good stabilization.

-Excellent fatigue properties.

-High strength and tear resistance.

-Product diversification.

-Chemical-Resistant and heat-resistant properties.