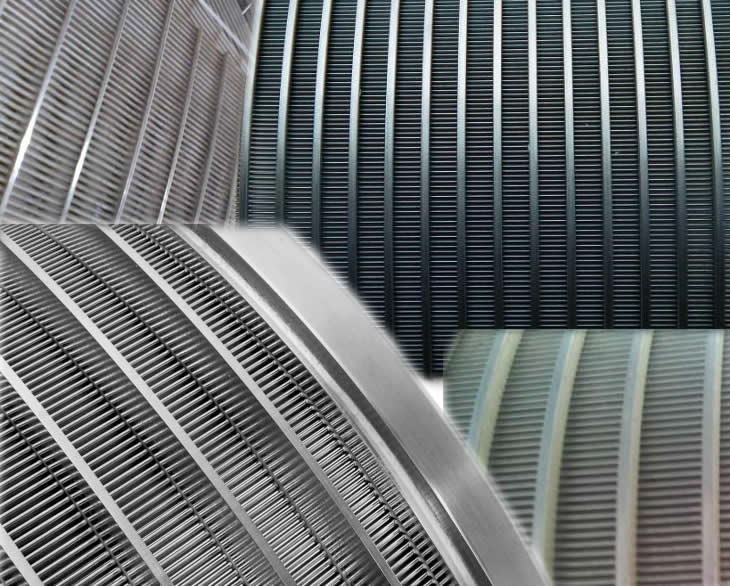

Sieve bends are wedge wire type dewatering and classifying screen panels in arc shape designed for high tension vibrating machines. Mostly made of galvanized steel or stainless steel 304 or 316 grade wire rod welding into slots. The vibrating screen has a continuous slot offering virtually non-clogging property, more open area and precise filtration. Also called DSM Screen as it is mostly used in mining industry and Dutch State adapts sieve bend in Mine development first. Actually, sieve bends as dewatering screen elements are now used for many industries, such as mud vibrating screen accessories for oil and mud under the conditions of solid-liquid sieve screening and filtration, as sugar cane mesh screen, mineral processing mesh and water treatment filters. A kind of rigid screening filter with uniform super welding quality and stability, high opening rate, high strength, stiffness and load capacity.

Sieve Bends Structures:

Sieve bend has a slotted screen structure with a trapezoidal wire section. The slot is wide at top and then narrows down. The mining sieve consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. This curved metal screen surface has greater solid-liquid-seperation capacity than a flat screen surface for fluid flow.

The v wire profile stainless steel mesh screen is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods with automatic wire screen machine. Each wedge wire and support rod are welded by resistance welding to form slot openings of precise aperture.

Hence, the vibrating sieve bends or DSM mesh has a structure with individually replaceable cross unit, flat bar runner system for woven wire decks, automatic alignment of tensioning bolts for side tensioned wire mesh deck panels and stress relieving technology in design.

Mesh Materials:

1. Stainless steel 304, 304L, 316, 316L, also monel, manganese steel, high carbon steel, low carbon steel, high manganese steel, or polyurethane and special material according to the customer request.

2. Opening /Slot: 0.02mm -- 6.0mm (Can be customized)

3. Pitch: 10mm -- 35mm

4. Max Length: 6m

5. Support Wire : V-Wire, Round wire etc.

Applications:

Profile wire mesh bends panels are mainly used in Sugar mill; Mineral processing;Waste water cleaning up;Condensate water filtration;Column bottoms purification; 45°DSM screen is suitabe for thickening and screens;120°DSM screen is used for separating water suspension. Basically, ZSM and DSM This wedge wire Dewatering Screen is widely used in metallurgy industry, such as sinter ore, sintering and palletizing, ore classification in mine industry, classification dehydration and referral, etc. This is the first choice for large sintering plant, Palletizing plant, Concentrator, Coal Preparation Plant, Coal Washrag and also the ideal substitutes of large vibration screen for the international mining and oil projects.

Slotted Wire Mesh Sieve Features:

Energy Efficient - operates with no moving parts and with no energy input;

Space Efficient - treats up to 122 litres per second per square metre of floor space;

High Tensile - suitable for various solid liquid filtration operation;

Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008");

Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation;

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools;

Flexible Design - we can supply units with any features you may require.

Specifications:

1) wire size: 0.75×1.5mm, 1×2mm, 2X3mm, 2.3×3mm, 3×5mm

2) Slot width: 0.5mm,1.0mm,

3) screen diameter: 25mm, 33mm, 37mm, 40mm, 60mm, 177mm,219mm,273mm,323mm

4) screen length: 5.8m,11.9m.

| Model | Number Of layers |

Sieve area(m2) |

Mesh size (mm) |

Maximum Feed size(mm) |

Capacity (mm) |

Frequency (r/min) |

Double Amplitude (mm) |

Power (kw) |

Dimension (Long×wide×high) |

Weight(kg) (Excluding motor complete) |

Sieve |

Screen surface specifications (mm) |

| SKS-1601 | 2 | 1.4 | 3-30 | 100 | 3-25 | 800-970 | 8 | 5.5 | 1930×1700×1600 | 680 | 20° | 900×1800 |

| SKS-1602 | 2 | 1.9 | 3-30 | 100 | 4-38 | 800-970 | 8 | 5.5 | 2490×1700×1800 | 1400 | 20° | 900×2400 |

| SKS-1603 | 1 | 2 | 3-30 | 100 | 5.12-37 | 900 | 8 | 5.5 | 2160×1770×1075 | 1400 | 20° | 980×2050 |

| SKS-1604 | 1 | 3.2 | 3-50 | 200 | 7.5-8 | 800-970 | 8 | 5.5 | 3073×2030×1611 | 1750 | 20° | 1200×3000 |

| SKS-1605 | 2 | 3.2 | 3-50 | 200 | 7.5-78 | 800-970 | 8 | 5.5 | 3122×2050×2247 | 2345 | 20° | 1200×300 |

| SKS-1606 | 3 | 3.6 | 5-50 | 200 | 15-86.3 | 940 | 8 | 7.5 | 3200×2145×2300 | 2700 | 20° | 1200×3050 |

| SKS-1607 | 3 | 3.9 | 3-50 | 200 | 9-93 | 800-970 | 8 | 11 | 3900×2300×2700 | 4000 | 20° | 1200×3600 |

| SKS-1608 | 2 | 5.7 | 5-50 | 400 | 50-208 | 800-970 | 8 | 15 | 4400×2610×2857 | 5336 | 20° | 1500×4200 |

| SKS-1609 | 3 | 6.4 | 5-30 | 400 | 22.5-162 | 800-970 | 8 | 15 | 5650×2528×3400 | 5800 | 15° | 11500×4800 |

| SKS-1610 | 1 | 8.64 | 5-100 | 400 | 22-206 | 755 | 11 | 15 | 4802×3009×2860 | 6089 | 20° | 1830×4880 |

| SKS-1611 | 2 | 8.64 | 5-100 | 400 | 25-206 | 750 | 11 | 15 | 4802×3009×2860 | 6189 | 20° | 1830×4880 |