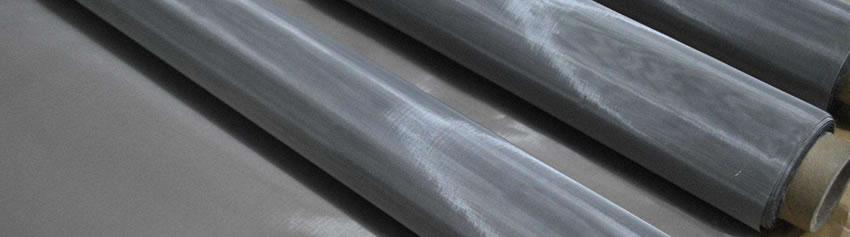

This tensile metal screen is designed to separate solids from liquids in hydraulic dewatering system. The tightly bonded rectangular metal screen is mostly constructed with strong perforated stainless or mild steel screen backing layer in addition to the tensioned stainless steel mesh cloth.

Popular models for export:

Tensile steel frame shale shaker screen model 25''*36.25'' API 60;

Scalping screen 300 primary 89 API50;

48 x 30 screen for API 35, 45, API230;

Screen size 29 inch x 42 inch for shale shaker series 500 fluid system;

Mud pump parts for rig up;

Mini panel screen (size 1251 mm x 635 mm x 25.4 mm) API50 for oil rig shale shakers;

API70 and API 100 (panel size 1251 mm x 635 mm x 25.4 mm) for shale shaker brands and models.

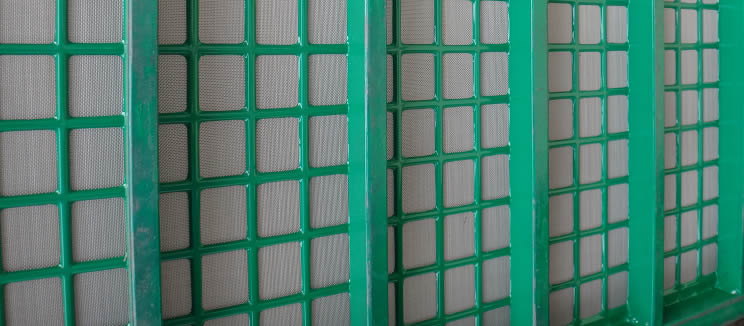

The metal flank grid allows high flow rates, accurate sizing and improved penetration rates and shaker capacities. The shale compound metal screen panels are used as screening parts in gas and oil drilling, in coal mining, mineral, petroleum, chemical, food, medicine, machinery manufacturing and other industries. The steel frame shall be sandblasted or rough ground finish at top to get good profile for powder coat.

Structures:

The frames and panels are fabricated parts for shale shaker screen. The panels are constructed with single, double and triple layer stainless steel mesh cloth bonded to the multi-rib steel support plank. The frame is made up of the high-strength square steel tube or flat steel welded to multi- ribbed construction. Wedeg fastening frame is now popularly used to achieve better tension effect. The metal mesh screen, divided into many independent small units by grids of the backing plate, can prevent rips or tears from spreading overmuch.

Material:

Frame and support grid: Carbon steel or stainless steel plate or tube

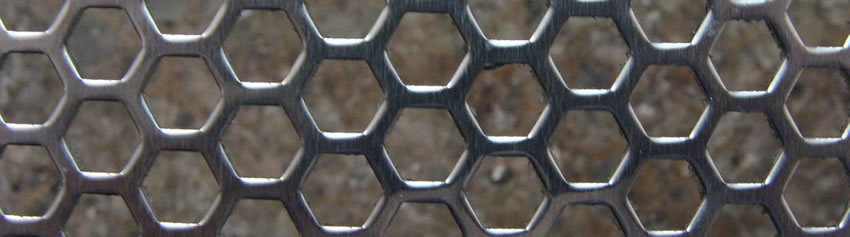

Mesh Cloth: Woven stainless steel wire cloth mesh, metal ss SUS302, 304, 316, 304L, 316L, plain woven and twill woven; hexagonal backing mesh of perforated metal steel. Stainless steel materials are ideal for acid, alkali, high temperature and work environments.

Hole Shape: Square mesh for filter cloth of ss mesh; hexaongal or custom for punched perforated metal plate layer.

Filter Rating: 99%.

Screen layer: 2 or 3 Layers

Mesh: 20-325 mesh

Screen Thickness: 2.0mm

Panel Length: 913-1253mm

Panel Width:585-720mm

Screen Panel: Weight:13 kg

Case Study of Popular Panels and Frames for Shaker Screen:

Mild steel A36,

14 gauge - 0.072” minimal thickness

Frame Material:

Mild steel A513.

1.00” x 1.00” tube - (14 gauge nominal wall thickness 0.083”) and

11.38’ per frame;

½” x 1.00” tube - (16 gauge nominal wall thickness 0.585 – specify .06 minimum) and

14.67’ per frame.

Weld corners: 1.00”: After corners welded – select one side of frame and weld all eight bars (1/2”x1.00” to 1.00” two welds on each side of tubing). Welds only need to be ground on outside corner. The long dimension typically cut a little shorter than 46.25’ (46.125’ to get good penetration and it minimizes the grinding of the welds).

Top of frame is sandblasted or rough ground to get good profile for powder coat.

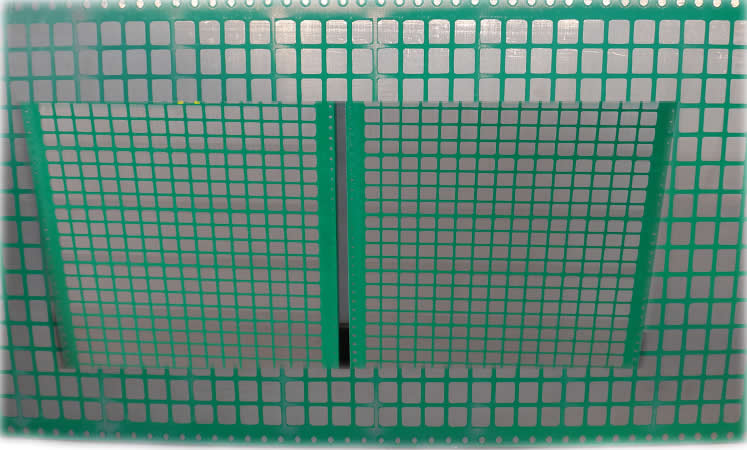

Repariable and Replacable Meshes for Screen Panels of Dimension: 23"*45.875"

Repariable and Replacable Meshes for Screen Panels of Dimension: 23"*45.875" Metal Grid for Added Support and Easy Repair

Metal Grid for Added Support and Easy RepairApplication

The framed metal screen makes the ideal equipment accessories of drilling fluid shale shaker, widely used in drilling operations under different conditions for screening slurries, mud separation, de-water solids, coal cleaning and screening of plastics and minerals. This vibratory filter screen is easy to change and clean. Bonding square or hexagonal support panel help maintain cut point integrity by stabilizing the sandwich screen, increasing durability by reducing screen flutter, and isolating any screen failures. The screen, may be repaired using the stainless steel plugs, applied with the panel or by application of, silicone rubber.

Features:

1,

Different layers screen offers different density. The mesh layers are arranged to get various screening effects;

2. High strength frame, multi-ribs and the mesh cloth with reasonable tension, forming a reliable combination panels, together bonded with wedge-shaped fastening device, suitable for high strength vibrating screening and industrial sifting screens;

3. The shale shaker screen frames are sturdy and strong with high-strength square steel tube welded to multi-ribbed construction;

4.

Accessary rubber plugs may be used to repair rips or tears.

5. The frames and the screen mesh stainless steel cloth can all be replaced and re-used to save cost.

Specifications:

We supply screen mesh from API 20 to API 400, with mesh ranging from 20 - 325.

Dimension (Length×Width): 585×1165mm, 635×1253mm, 913×650mm,720×1220mm, 712×1181mm.

Weight(kg): 12,13.5,12.5,17.

| Screen Model | Range of Mesh | Weight (Kg) |

| Standard-12 -A | 20 mesh - 325 mesh | 12.0 |

| Standard-12-B | 20 mesh - 325 mesh | 13.5 |

| Standard-12-C | 20 mesh - 325 mesh | 125 |

| Standard-12-D | 20 mesh - 325 mesh | 17.0 |

| Standard-12-E | 20 mesh - 325 mesh | 17.0 |